In www.xyreon.com.my evolving landscape, factory automation systems play a role in optimizing efficiency, productivity, and competitiveness . Malaysia, as a manufacturing hub, has embraced automation to improve operations and achieve higher levels of precision and output.

This article aims to provide Malaysians with a comprehensive understanding of factory automation systems, including their definition, functionality, and relevance in the context of Malaysia’s manufacturing sector.

What are Factory Automation Systems?

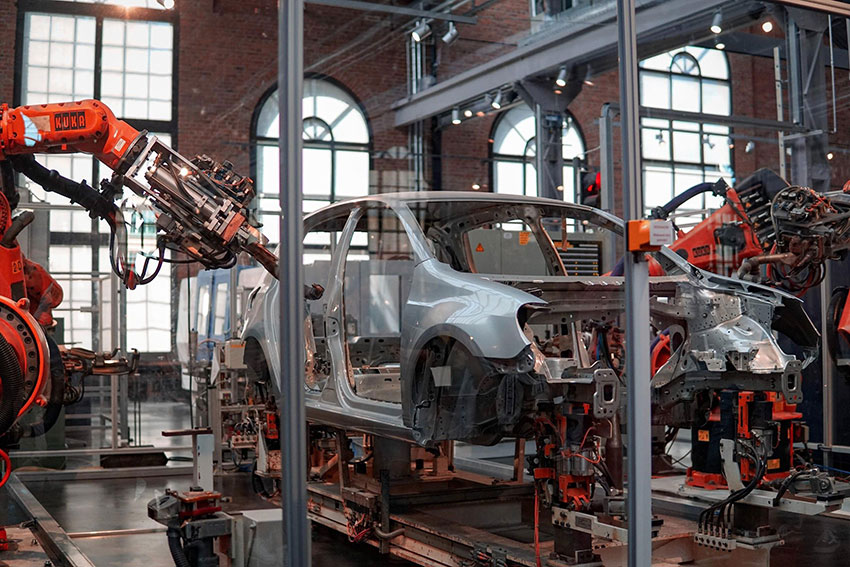

Factory automation systems refer to the integration of advanced technologies, such as robotics, artificial intelligence, and control systems, into manufacturing processes. These systems are designed to automate various tasks, reduce human intervention, and streamline production lines. From assembly lines to material handling, quality control, and data analysis, automation technologies revolutionize the way factories operate.

How do Factory Automation Systems Work?

Factory automation systems operate through a combination of hardware, software, and networked systems. Key components include:

Robotics and Machinery: Robots and automated machinery are utilized to perform repetitive tasks with speed, accuracy, and precision. These systems can handle complex operations, improving efficiency and reducing errors.

Sensors and Vision Systems: Sensors and vision systems provide real-time data on production processes, ensuring quality control and identifying anomalies. They enable machines to detect, measure, and respond to changes in the environment or product specifications.

Control Systems: Centralized control systems monitor and coordinate the activities of various automated machines and devices. These systems optimize production flow, regulate parameters, and enable seamless integration of different components.

Data Analytics and Artificial Intelligence: Automation systems leverage data analytics and artificial intelligence to gather insights, identify patterns, and make data-driven decisions. Predictive analytics can optimize maintenance schedules, prevent breakdowns, and enhance overall productivity.

Relevance of Factory Automation Systems in Malaysia

Factory automation systems hold significant relevance in Malaysia’s manufacturing sector due to several factors:

Enhanced Productivity: Automation streamlines production processes, reducing cycle times, minimizing errors, and optimizing resource utilization. This leads to increased productivity and output, allowing Malaysian manufacturers to meet market demands efficiently.

Cost Reduction: Automation reduces labor costs, as machines perform tasks that were previously done manually. It also minimizes the risk of human errors and associated costs. Moreover, predictive maintenance and real-time data analysis help avoid unexpected breakdowns, reducing downtime and associated losses.

Quality Control and Consistency: Automation systems enable consistent and precise production, resulting in higher quality products. Sensors and vision systems detect defects or variations, ensuring adherence to stringent quality standards. This enhances the reputation of Malaysian manufacturers in global markets.

Skills Development and Job Opportunities: The adoption of automation in Malaysia’s manufacturing sector necessitates a skilled workforce to operate, maintain, and program these systems. This drives the need for upskilling and creates new job opportunities in fields such as robotics, programming, and maintenance.

Conclusion:

Factory automation systems have become indispensable for the growth and competitiveness of Malaysia’s manufacturing sector. By leveraging advanced technologies and streamlining production processes, these systems enhance productivity, reduce costs, and ensure high-quality output.

Malaysian manufacturers embracing automation can meet market demands effectively while nurturing a skilled workforce. As Malaysia continues to move towards Industry 4.0, the integration of factory automation systems will be vital in driving innovation, sustainability, and global competitiveness.